Introduction

With the increasing demand for energy and the depletion of conventional oil and gas fields, the development of oil and gas reserves in offshore regions has received considerable attention in the oil sector. Offshore oil fields, particularly in deep-water and isolated regions, have become immensely important in the context of this increased energy demand. However, such oil fields face considerable operational difficulties arising from severe environmental and complex geological conditions. To overcome such difficulties, extended reach wells (ERWs) have been recognized as an effective technology in accessing oil reserves in offshore regions with minimal requirements for multiple production platforms. ERWs make significant contributions towards improving the recovery factor, decreasing expenditures linked with the required infrastructure, and achieving greater economic efficiency. Challenges related to the operation of ERWs arise in association with subsurface formation in offshore regions.

Table 1

Summary of literature review

|

Authors |

Key features |

Results |

Main defferences |

|

Hareland et al. (2010) |

ROP prediction based on drilling bit and rock interaction Enhanced ROP prediction with drilling bit wear considerations Specialized in the prediction of ROP, but could not optimize multiple parameters simultaneously |

Rising ROP prediction by incorporating drill bit wear |

Specialses on ROP prediction, but does not optimize deferrent parameters simultaneously |

|

Jin and Wang (2012) |

Include ROP equation of PDC drilling bit and wear equation |

Improve drilling cost and ROP |

Dual-objectiv optimization (cost and ROP), less consideration of other drilling parameter |

|

Cui et al. (2014) |

Uses MSE as the optimization objective |

Optimized drilling parameters using MSE |

Focuses on MSE as the sole objective, does not consider multiple objectives or drilling cost |

|

Wang et al. (2017) |

Modified Younger's ROP equation, drilling bit life, and MSE |

Improved drilling efficiency through multi-objective progressing |

Uses an improved multi-objective approach bu |

|

Hegde et al. (2020) |

Models ROP, MSE, torque, and stick-slip using decision variables |

Optimized WOB, RPM, flow rate, and rock strength for better drilling |

Uses machine learning (random forest) to mprove drilling parameters, but does not include multi-objective optimizatio |

|

Alali et al. (2021) |

Maximizes ROP, minimizes non-productive time (NPT) |

Optimized ROP and NPT, improving drilling process efficiency |

Hybrid approach combining data-driven optimization, focuses on reducing NP |

|

Semnani et al. (2021) |

Global optimization with a population-based method |

Achieved optimal well location and parameters, rising net present value |

Focuses on maximizing net present value (NPV) using global optimization, which differs from standard drilling efficiency goal |

|

Song et al. (2022) |

Multi-objective optimization using MSE and UFC |

Real-time optimization of WOB, RPM, and displacement volume |

Incorporates pump equipment limitations as a constraint in real-time optimizatio |

|

Qu et al. (2023) |

Minimizes UFC and MSE using hierarchical sequence and particle swarm algorithm |

Achieved optimal selection of drilling parameters |

Focuses on minimizing UFC and MSE, with the applicat sequence method |

|

Wang et al. (2024) |

Input data includes geological data from adjacent wells, real-time logging, and downhole parameters; constraints on machine and pump limits |

Maximized drilling bit energy efficiency, minimized drilling cost, and identified optimal drilling parameters in real time |

Based on the dual-objective optimization of MSE and UFC, and using Bayesian optimization to achieve efficient parameter adjustmen |

In general, there is much research on drilling parameters optimization using intelligent methods, and the theory is relatively mature, but there are still some problems. On the one hand, the objective function of optimization in most studies is single-objective or dual-objective, typically focusing on maximizing ROP, minimizing MSE or minimizing UFC. However, few studies have considered the three models as the objective functions in the optimization process simultaneously, and the influencing factors considered are not sufficiently comprehensive. On the other hand, few scholars in various countries have applied intelligent optimization of drilling parameters to ERWs without considering the azimuthal angle, overlooking the influence of rock anisotropy on drilling in different directions.

2. Correlation analysis of factors affecting ROP in ERWs

2.1. Overview of data

The goal of the work presented in this study is to improve the rate of penetration (ROP) of ERWs by using intelligent optimization methods to identify ways in which ROP can be increased as well as the means by which to improve ROP. Improving ROP through intelligent optimization means understanding how to collect, store, and use data from multiple sources (drilling companies, equipment manufacturers, etc.) in such a way that the correlation between ROP and the individual parameters being tested is maximized. It also means ensuring that the available datasets are sufficient for creating a machine learning model, both in terms of volume of data and the number of samples used for analysis.

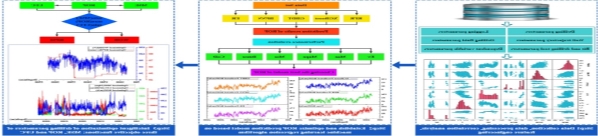

Fig. 1. Flow chart of drilling parameters optimization process

2.2. Correlation coefficient calculation

Computing the correlation coefficient is a crucial operation in machine learning since it is often used for data pre-processing techniques including the feature engineering stage in model development. The performance of a machine learnig model heavily depends on the quality of input data and features since models and algorithms can only try to capture what is already there in the feautres. Thus, careful data preparation and analysis are important for obtaining best performance. As part of data preprocessing, feature engineering includes the process of selecting and extracting features to determine the most relevant ones for a given task. With the help of arithmetic correlation between features and target label, significant factors can be separated out from unsignificant. Several measures are used to assist in the assessment. If data is quantitative and normally distributed, then Pearson’s correlation coefficient would be appropriate. When the normality assumption is violated, however, the Spearman correlation coefficient can serve as a useful substitute. Kendall's correlation coefficient is particularly useful for ordered categorical variables. In addition to above mentioned techniques, grey relation analysis (GRA) is another method for analyzing the interactions. GRA analyzes the grey correlation relationship of data sequences and curve patterns according to their similarity in geometric structure.

References:

- Alali et al., 2021,A. M. Alali, M. F. Abughaban, B. M. Aman, S. Ravela,Hybrid data driven drilling and rate of penetration optimization,J. Pet. Sci. Eng., 200 (2021), Article 108075, 10.1016/j.petrol.2020.108075

- Deng et al., 2024,S. Deng, H. Y. Pan, H. G. Wang, S. K. Xu, X. P. Yan, C. W. Li, F. Zhao,A hybrid machine learning optimization algorithm for multivariable pore pressure prediction

- Hareland et al., 2010, G. Hareland, A. Wu, B. Rashidi,A drilling rate model for roller cone bits and its application