1. Introduction

Sidetracking is the term used for drilling a directional hole to bypass an obstruction in the well that cannot be removed or damage to the well, such as collapsed casing that cannot be repaired. Other applications of sidetracking are deepening a well or relocating the bottom of the well in a more productive zone (Oil and Gas Well Drilling and servicing eTool). To sidetrack, a hole (window) is made in the casing above the obstruction. The area below the window is then plugged with cement. In order to drill off the sidetrack at a desired angle from the main well, drill tools such as a whipstock, bent housing, or bent sub are employed (Oil and Gas Well Drilling and Servicing eTool). In the 1920’s whipstocks were firstly used as a correctional device in the fields of California. This correction was conducted to divert around a fish or to bring the well back to vertical. Another use of the whipstock was to drill relief wells in case there was a surface or underground fire. Later this tool was used to intentionally deviate the well from vertical direction. Then, the word whipstock became increasingly synonymous with sidetracking. The alternate methods like knuckle joints and deflectors, used during 1920’s and 1930’s, were not as predictable as sidetracking.

2. Side-track definition

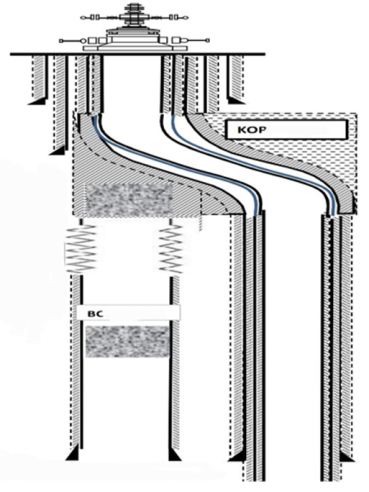

To create a new hole from an existing well, utilise a side-track. This procedure entails plugging a well's lower portion for geological or instrumentation reasons, or when an instrumentation attempt fails.

Note: If this side-track follows refishing instruction, make sure the trim is in perfect condition and does not require an inspection before starting any side-track. [5].

Fig. 1. Side-Track illustration

3. Factors influencing the decision to sidetrack

Commercial and economic implications may be a significant deciding factor in determining whether to sidetrack. Oil is a valuable commodity and in some cases, significant sums of money can be tied up in the completed well. As such, efforts to salvage the operation through sidetracking can be well justified. On the other hand, the alternative to sidetrack, which would be to write off the attempt as a failure and move elsewhere, might prove more cost-effective in the short term. Other deciding factors may relate to the relative danger or difficulty of the different options available. For example, returning to the surface by pulling the drill string might be a simpler operational solution when compared to sidetracking, particularly if the deviation is large.

On the other hand, we know that pulling the drill string is a dangerous operation that can lead to tool failures downhole, and it is also time-consuming and expensive. Equally, there may be good operational and technical reasons for preferring certain options over others. For example, the drill string may have become jammed due to a failure of the BHA. Replacing the BHA and trying to force the drill string through the original hole might represent a technical option, but there is a risk that the drill string will become jammed again, perhaps irretrievably. By sidetracking a new hole, the problematic BHA can be bypassed and the original hole may become a viable second string or injection target. This method of avoiding or sidetracking around problem zones is sometimes known as 'geosteering'. This also reflects a type of decision-making process in the round. All of these different factors, both commercial and technical, will likely be taken into account when considering the best way to remove a drill string that has become jammed in the bore. This decision will be made by an appropriate 'responsible person' who will evaluate any options presented by 'competent persons' in the light of the various different factors in play. It is also worth bearing in mind that the relative significance of different factors may be influenced by the local geology and operation in progress. For a given well and a given obstacle, the balance between costs and the potential success of well clearance might be assessed quite differently elsewhere. [6].

4. Benefits of sidetrack

— It provides a significantly less time-consuming alternative to the approach of building up such a wellbore network by means of repeated drilling and reworking to prolong the life of existing wells.

— Optimize production from mature fields and enhance the overall efficiency of hydrocarbon extraction.

— This procedure greatly reduces the economic effects of having to spend much more money to design a wellbore.

— The ability to drill a branch well from an existing wellbore at a suitable angle is a critical part of wellbore design and fulfills needs which are not addressed by prior art solutions.

5. Determination of the stuckpipe point

When the loosening tests have given no results, it is necessary to unscrew (back off) the free part of the drillstring. But for this it is necessary to determine the position of the stuckpipe point. Two methods exist to determine the stuckpipe point:

— A mechanical method by measuring the elongation (extensiometry) of the stuck fitting, gives an approximate knowledge of the unstuck point but allows us to anticipate the program and the equipment necessary for the intervention after unscrewing.

— An electrical measurement called the «Free Point Indicator» which gives excellent results in heavy pipes and pipes, but is often questionable in drill collars. [10]

6. Sidetrack Process

6.1. Decision

In some cases, when the fish can no longer be recovered by a simple procedure such as overshot fishing, and it seems necessary to consider an overdrilling operation, the decision maker may wonder whether it would not be more economical to abandon the fish and carry out a sidetrack. If the costs of the materials and the drilled part to be abandoned are relatively easy to estimate, it is on the other hand more difficult in the case where we continue the instrumentation with the objective of definitive recovery of the fish, to evaluate the duration required for these operations. The decision to continue or not the recovery operations is therefore necessarily subjective. A rigorous cost analysis procedure can, however, provide useful information to the decision-maker.

The cost price of a side track operation depends on the following costs:

— The cost of fish to abandon.

— (B) the cost of the deviation.

— (C) The cost of days spent instrumenting.

— (D) The cost of service companies involved in instrumentation.

— (E) The cost of repairing the equipment recovered from the well, E can be equal to A. [10]

6.2. Decision parameters (cost)

— As long as and if:

A + B > C + D + E

Instrumentation is recommended and or can continue.

— If:

A + B = C + D + E

instrumentation is not recommended

— If:

A + B < C + D + E

Instrumentation Must stop immediately. [10]

6.3. Zone selection (KOP)

When making the side-track decision, it is necessary to search for the area where the formation presents the characteristics most likely to allow a side-track. This operation is done by analyzing the advancements encountered in the previous well. The ideal formation is a consolidated formation associated with a high penetration speed and a calibrated hole.

In all cases, you should avoid starting the side-track in clay due to the risk of cave-in at the start of the deviation. The minimum distances taken into account for creating a side-track are generally based on a variation in angle. of the order of 1°/10 m.

Therefore we will take as the minimum vertical height necessary for its realization:

— Phase 6" = 12 meters + 50 % of security = 18 meters.

— Phase 8 1/2" = 12 meters + 50 % of security = 18 meters.

— Phase 12 1/4" = 17 meters + 50 % of security = 25 meters.

— Phase 17 1/2" = 25 meters + 50 % of security = 37 meters. [10]

6.4. Side track in open hole

- Lower the pipe or tubing extension at the side where the cement plug is placed.

- Place the cement plug.

so as to cover a minimum of 15 m above the coast chosen for the start of the side-track. The formulation of this cement must be such that it makes it possible to obtain a very hard cement in 24 hours.

7. Side track in the casing with use of the «Whipstock»

In the case where the casing is well cemented and in good condition (absence of corrosion or deformation) this technique is the safest. As for the other methods the choice of the side-track zone will be made based on the training encountered. The minimum window length necessary to exit the casing in this case is 9 meters. It is necessary to avoid having a sleeve and centralizers in the opening zone and it will be necessary to carry out a CCL and a CBL for confirmation. [10]

References:

- Document SH-FOR.

- Aljuzayri, Mohammed, Sarvodaya Bansal, Daria Ponomareva, Nata Franco, Mauricio Corona, and Jesus Levario. «Technological and Engineering Evolution to Successfully Drill Long and Highly Deviated S-shape Wells». In SPE Middle East Oil and Gas Show and Conference, p. D011S008R001. SPE, 2023. [HTML]

- Sonatrach production division«Programme de Work-Over IA-117z Préparation /Réalisation d’un drain vertical», Hydra le 13.02.2013.

- Mosli-Sonatrach «The instrumentations in drilling back off and side track» 07. May.2014.