Introduction

The Karsovayskoye Field, often referred to in literature as Kharasaveyskoye due to transliteration variations, is a major gas condensate field in Russia's Arctic region. Discovered in the 1970s, it spans both onshore and offshore segments in the Kara Sea, with reserves estimated at over 2 trillion cubic meters of gas. Development began in earnest in 2019, with initial drilling focusing on horizontal wells to access the Cenomanian and Valanginian formations. The field's remote location and harsh environmental conditions necessitated innovative drilling strategies to maximize recovery while minimizing infrastructure needs. Multilateral drilling involves creating multiple lateral branches from a primary wellbore, often in directional (non-vertical) trajectories. This technology, pioneered in Russia as early as the 1950s in Bashkiria fields, allows for greater reservoir exposure without additional surface footprints. In directional wells, the main bore is deviated from vertical to target specific zones, and branches are kicked off using tools like whipstocks or milling assemblies. At Karsovayskoye, this approach was critical for tapping into compartmentalized reservoirs, where single horizontal wells could not achieve optimal drainage.

This case study outlines the geological context, drilling methodology, implementation phases, results, challenges, and future implications, providing a comprehensive view of how multilateral technology has been applied in this Arctic setting.

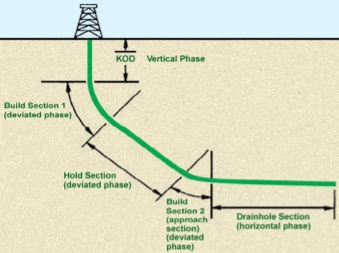

Fig. 1. Directional Drilling — an overview | ScienceDirect Topics

Diagram illustrating multilateral drilling in directional wells, showing branching laterals from a deviated main bore.

Geological and Reservoir Background

The Karsovayskoye Field lies in the West Siberian Basin, characterized by thick sedimentary sequences of Jurassic and Cretaceous age. The primary reservoirs are in carbonate rocks with high heterogeneity, including fractures and vugs that enhance permeability but introduce drilling risks like lost circulation. Porosity ranges from 10–20 %, with permeability varying from 1–100 mD, leading to uneven fluid flow. Directional drilling was employed to navigate the dipping strata, with inclinations up to 60 degrees. Multilateral branches targeted isolated pay zones, increasing contact area by 2–3 times compared to single-laterals. Seismic data and borehole imaging from laterolog resistivity tools helped map faults and optimize branch placement. The field's offshore extension required extended-reach drilling from onshore pads, similar to techniques used in nearby Bovanenkovskoye Field. This minimized environmental disturbance in the sensitive Arctic ecosystem.

Fig. 2. Map showing the location of the Karsovayskoye Field in Russia's Yamal Peninsula, highlighting onshore and offshore segments

Drilling Technology and Implementation Planning and Design

Pre-drilling planning utilized 3D geological models integrated with data from offset wells. Software like Well Architect simulated trajectories, assessing risks such as torque and drag. Multilateral junctions were classified under TAML (Technology Advancement for Multilaterals) levels: Level 4 for cased and cemented junctions, ensuring mechanical integrity and hydraulic isolation. Directional tools included rotary steerable systems (RSS) for precise control, allowing deviations without sliding. Bottom-hole assemblies (BHAs) featured measurement-while-drilling (MWD) and logging-while-drilling (LWD) for real-time data.

Execution Phases

- Main Bore Drilling: The primary well was drilled vertically to 1,500m, then deviated to 3,000m true vertical depth (TVD), reaching a measured depth (MD) of 4,500m. Mud systems with low toxicity were used to combat formation damage.

- Junction Creation: At the kick-off point, a whipstock was set to mill a window in the casing. The first lateral was drilled horizontally for 1,200m into the upper reservoir.

- Additional Branches: Up to three branches were created, each 800–1,000m long, using retrievable tools to re-access the main bore. Completions involved swellable packers for zonal isolation. By 2025, over 16 wells incorporated multilateral designs, with drilling rates averaging 200m/day despite Arctic winters.

By 2025, over 16 wells incorporated multilateral designs, with drilling rates averaging 200m/day despite Arctic winters.

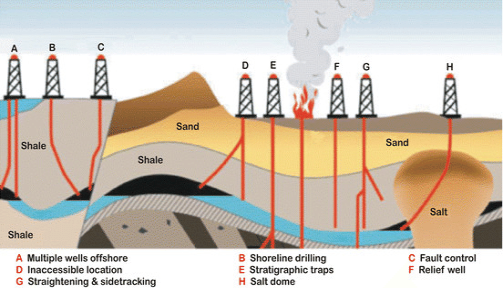

Fig. 3. The application of directional drilling (Sebastian et al. 2016...)

Schematic of a directional well with multilateral branches, depicting junction points and lateral extensions

Results and Benefits

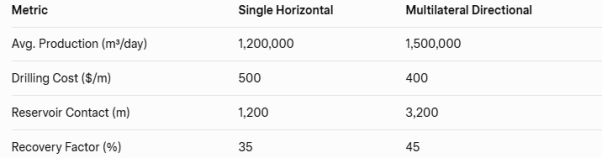

Initial production from multilateral wells at Karsovayskoye averaged 1.5 million cubic meters of gas per day per well, a 25–30 % uplift over single-horizontal counterparts. Cumulative output exceeded 50 billion cubic meters by mid-2025, contributing to Russia's record drilling boom despite sanctions. Economic benefits included a 20 % reduction in capital expenditure by consolidating multiple wells into one surface location. Environmentally, fewer pads reduced land use by 40 %, aligning with sustainable Arctic development. Comparative analysis with nearby Vankor Field showed similar gains, where multilateral horizontals improved recovery factors from 35 % to 45 %.

Oil Gas Drilling Rig Russia Stock Photo 222278692 | Shutterstock

Fig. 4. Photo of a drilling rig operating in a Russian Arctic oil field, similar to those used at Karsovayskoye

Challenges and Solutions

Key challenges included high-pressure zones causing blowouts and tool failures in extreme cold (-50°C). Solutions involved advanced mud rheology and insulated equipment. Geological uncertainties were mitigated by borehole imaging, reducing non-productive time by 15 %. Sanctions post-2022 limited access to Western technology, but Russian firms adapted by localizing services, maintaining drilling momentum.

Conclusion

The successful implementation of multilateral drilling in directional wells at Karsovayskoye demonstrates the technology's viability in challenging environments. It has not only boosted production but also set a precedent for Arctic field development. Future expansions may incorporate intelligent completions for real-time monitoring, further enhancing efficiency. As Russia continues to lead in drilling innovations, lessons from Karsovayskoye can inform global practices in mature and frontier basins. continues to lead in drilling innovations, lessons from Karsovayskoye can inform global practices in mature and frontier basins.

Fig. 5. Multilateral Wells Drilling Technology Full Guide — Drilling Manual

Detailed schematic of multilateral well configurations used in the field

References:

- Multilateral Well Placement in Carbonates: https://onepetro.org/SPERPTC/proceedings-abstract/20RPTC/2–20RPTC/D023S009R003/450175

- Gazprom Drilling at Kharasaveyskoye: https://www.ogj.com/drilling-production/drilling-operations/article/14177950/gazprom-begins-drilling-first-production-well-at-kharasaveyskoye-field-in-yamal

- Russian Drilling Technology Insights: https://www.ogj.com/home/article/17226380/pioneering-work-economic-factors-provide-insights-into-russian-drilling-technology