Introduction

The construction of production directional wells involves drilling at controlled angles to target specific subsurface formations, often in complex geological environments such as offshore or densely populated oil fields. Drilling fluids are essential for this process, providing hydrostatic pressure to prevent wellbore collapse, lubricating the drill string, and removing rock cuttings. However, inefficient preparation and treatment of these fluids can lead to increased downtime, higher material costs, and environmental hazards from waste disposal. Recent advancements emphasize high-efficiency, environmentally friendly systems. For instance, ultra-high-density fluids and intelligent recycling technologies are being developed to handle deeper wells and reduce ecological footprints. This article examines these technologies, drawing from industry research and case studies to highlight their efficiency in oil field applications.

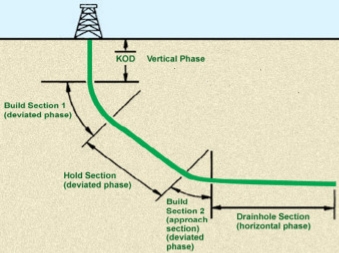

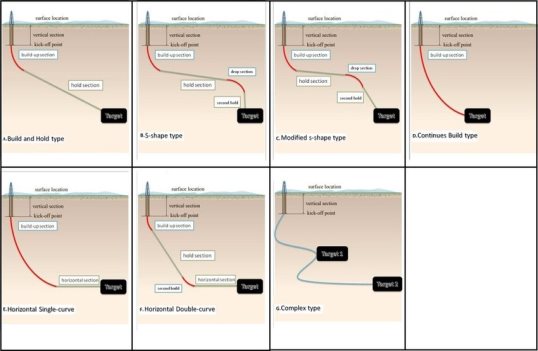

Fig. 1. Directional Drilling — an overview | ScienceDirect Topics

Importance of Drilling Fluids in Directional Wells

In directional wells, fluids must maintain rheological properties under high shear rates and temperatures. Poor fluid management can cause issues like stuck pipes or formation damage, reducing production rates. Efficient preparation ensures consistent viscosity and density, while treatment allows for recycling, minimizing fresh water and additive usage.

Background on Directional Wells and Drilling Fluids

Directional drilling techniques allow wells to deviate from vertical paths, enabling multiple wells from a single surface location ideal for clustered oil fields.

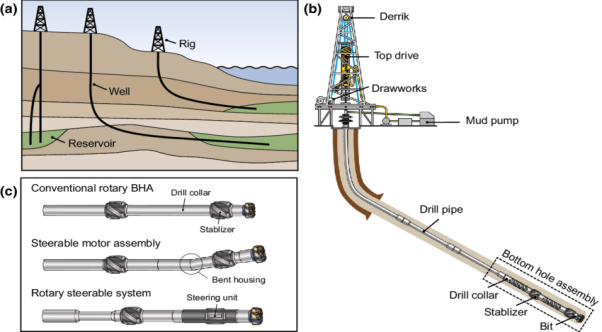

Fig. 2. a) applications of directional wells: single surface location for...

This method is particularly useful in offshore environments or areas with environmental restrictions, where minimizing surface footprint is crucial. Drilling fluids are classified as water-based, oil-based, or synthetic-based. Water-based muds (WBM) are cost-effective and environmentally friendly but may not suffice in reactive shales. Oil-based muds (OBM) offer superior lubrication and stability but pose disposal challenges. In directional wells, fluids must also facilitate steering tools like rotary steerable systems (RSS) and measurement-while-drilling (MWD) equipment.

Challenges in Oil Field Environments

Oil fields often feature high-pressure, high-temperature (HPHT) conditions, requiring fluids with enhanced thermal stability. In fields like those in mainland China or ultra-deep reservoirs, mud loss and contamination are common, necessitating advanced treatment. Efficiency is measured by metrics such as rate of penetration (ROP), non-productive time (NPT), and waste volume reduction.

Preparation Technologies for Drilling Fluids

Preparation involves mixing base fluids with additives like bentonite, polymers, and weighting agents. Traditional methods use manual mixing pits, but modern systems employ automated blenders for precision.

Automated Mixing Systems

High-efficiency mixers, such as those integrated with centrifugal pumps and hoppers, ensure uniform distribution of additives. In large-scale operations, like horizontal directional drilling (HDD) in oil fields, these systems reduce preparation time by 20–30 %.

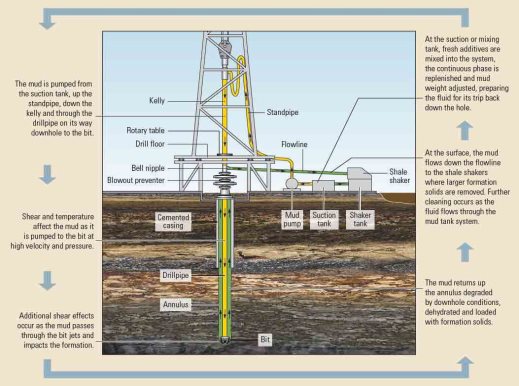

Fig. 3. eTool: Oil and Gas Well Drilling and Servicing — Drilling — Mud...

For example, pulsation techniques at 10–20 Hz minimize mud deposition, enhancing fluid quality.

Additive Innovations

Lubricating additives improve energy efficiency by reducing friction. Laboratory tests on devices like the Fann EP/Lubricity Tester show that these additives can lower torque by up to 15 %, beneficial for directional trajectories. In OBM preparation, aqueous phase optimization prevents emulsion instability, improving well completion quality.

On-Site Preparation in Oil Fields

In fields like Altyguyi, real-time monitoring of mud properties during preparation ensures sustainability. Trends include using low-density materials like hollow glass beads to achieve densities as low as 0.78 g/cm³, recyclable for cost savings. (Approximate page break

Treatment and Recycling Technologies

Treatment removes contaminants like cuttings and gases, while recycling reconditions fluids for reuse. This is vital in directional wells where fluid volumes can exceed thousands of barrels.

Solid Control Equipment

Shale shakers, hydro cyclones (desanders/desilters), and centrifuges separate solids. Efficiency exceeds 90 % in solid-phase separation, recovering over 90 % of water.

Fig. 4. HDD & CBM Mud Recycling System — GN Solids Control

Packaged mud recycling systems, including mud guns and agitators, process fluids at twice the rig flow rate for optimal cleaning

Advanced Recycling Systems

In HDD applications adapted to oil fields, systems like KOSUN's HDD mud recycling handle purification, mixing, and storage in one unit, reducing tank dimensions. Innovations include filtration of returned slurry and additive reinjection, saving bentonite usage. For large-diameter boreholes, mud return models using Power Law rheology predict flow directions, optimizing pump placements.

Environmental and Intelligent Features

Modern fluids focus on clean, recyclable formulations with minimal environmental impact. Intelligent systems monitor viscosity, density, and temperature in real-time, adjusting compositions automatically. Waste disposal methods, such as solidification or reinjection, further enhance sustainability.

Efficiency Analysis

Efficiency is quantified by cost savings, ROP improvements, and environmental metrics. Recycling systems reduce mud costs by 30–50 % and extend equipment life.

Fig. 5. The Defining Series: Drilling Fluid Basics | SLB

In directional wells, optimized fluids increase ROP by maintaining borehole stability, potentially shortening drilling time from 50–60 days.

Economic Benefits

Studies show that lubricating additives and efficient treatment lower energy consumption in waste management. In Chinese HDD projects, recycling saves additives and reduces disposal costs .

Environmental Impact

Recycling minimizes freshwater use and waste volume, aligning with regulations. Solid control achieves high separation rates, reducing ecological footprints.

Performance Metrics

In ultra-deep wells, advanced fluids enable intelligence and recycling, improving overall efficiency. Case studies from major innovations indicate faster production and compliance.

Case Studies

In mainland China's large HDD river-crossing projects, integrated recycling systems handled 1–3 m³/min flows, reusing mud effectively.

Fig. 6. Directional Drilling well types | Download Scientific Diagram

Similarly, in Altyguyi field, trend analysis improved drilling sustainability. American Augers' M200D system for HDD demonstrates reduced wear and higher penetration rates in oil field adaptations. Wellbore cleanup treatments compatible with drill-in fluids enhance completion efficiency.

Conclusion

Efficient drilling fluid preparation and treatment technologies are pivotal for successful construction of production directional wells in oil fields. Advancements in automation, recycling, and additive formulations drive cost reductions, environmental benefits, and operational improvements. Future trends point toward smarter, greener systems to meet the demands of deeper and more complex reservoirs. By adopting these technologies, the industry can achieve sustainable growth.

References:

- Increasing the Efficiency of Drilling Intervals of wells Composed of... — https://www.earthdoc.org/content/papers/10.3997/2214-

- 4609.2025510021?crawler=true Deep and ultra-deep oil and gas well drilling technologies — https://www.sciencedirect.com/science/article/pii/S2352854022000171

- [PDF] Engineering aspects and improvement of well drilling technologies... — https://technicalscience.com.ua/web/uploads/pdf/ME_15 %282 %29_2024_9–20.pdf

- Improving energy efficiency in well construction through the use of... — https://iopscience.iop.org/article/10.1088/1742–6596/1728/1/012031/pdf

- Improving Energy Efficiency in the Management of Drilling Waste... — https://www.mdpi.com/1996–1073/18/4/788

- Drilling, Completing, and Producing from Oil and Natural Gas Wells — https://understand-energy.stanford.edu/energy-resources/fossil-fuel-energy/drilling-completing-and-producing-oil-and-natural-gas-wells

- Research of oil-based drilling fluids to improve the quality of wells... — https://www.researchgate.net/publication/337820313_Research_of_oil-based_drilling_fluids_to_improve_the_quality_of_wells_completion

- Major Innovations in Oil & Drilling Technologies — Techs Research — https://www.techsciresearch.com/blog/major-innovations-in-oil-drilling-technologies/3390.html

- Adding Value to Well Completions via Effective Wellbore Cleanup — https://onepetro.org/SPEATCE/proceedings/01ATCE/All-01ATCE/SPE-71687-MS/134192