In order to ensure the safety of train traffic in the leading countries, the technology of work on monitoring the condition of rolling stock during the passage of trains through sections has been introduced on railways. The technology includes a system for contactless monitoring of the lower oversized rolling stock and the condition of the roller axle boxes of wagons on the train.

Keywords: dimensions, rolling stock, cars, railway, axle boxes, control.

The main purpose of the work technology is to identify malfunctions in passing trains that threaten traffic safety, take measures to immediately stop by all available means, prevent further movement of faulty wagons without eliminating defects or uncoupling them from trains.

Timely identification and troubleshooting of wagons in operation allows you to prevent the occurrence of irreversible failures that can lead to accidents and wrecks, increase the speed of trains, reduce the time spent on maintenance of trains, increase the distances of non-stop trains without maintenance, and ease the working conditions of line workers of the wagon industry.

The means of monitoring the technical condition of railway rolling stock include:

— overheated axle box detection systems

— Braking wheelset detection systems

— Drag detection systems

— Wheel defect detection systems

— systems for detecting violations of the upper dimension

— railcar overload detection systems

There are five types of «alarming» indications:

— a KTSM reading with the «Alarm 0» level indicates that the axle box is heated above the limit (set by setting the KTSM post to a set heating temperature) and requires inspection of the axle box at the nearest PTO along the train;

— the KTSM reading with the «Alarm 0D» level (regardless of the post setting) indicates an increase in the heating temperature of the axle box and requires inspection at the nearest PTO along the train;

— the indication «Alarm 0P» is generated by the AS KPS system based on automatic analysis of hidden KTSM readings, inspection is necessary at the nearest PTO along the train;

— indication «Alarm 1» — the pre-emergency heating level of the axle box, at which it is allowed to follow the train with special vigilance to the nearest station for inspection;

— the indication «Alarm 2» is an emergency heating level at which further train travel is not allowed. An immediate stop of the train and inspection of the axle box is required.

Overheated axle box detection systems

Overheated axle box detection systems provide contactless monitoring of the temperature of the axle box housings, which characterizes the technical condition of the axle box bearings, recognition of defective axle boxes according to certain criteria, transmission and registration of information about the presence and location of such boxes on the train.

At the same time, the controls give a signal about the appropriate heating level of the «Alarm-0», «Alarm-1» or «Alarm-2» boxes.

Braking wheelset detection systems

The braking wheelset detection systems provide contactless monitoring of the temperature of the wheel hubs of each moving unit, characterizing the presence of friction of the brake pads on the wheel rim, recognition according to certain criteria of a moving unit with faulty braking equipment, transmission and registration of the information received with theissuance of an Alarm-1 signal.

Drag detection systems

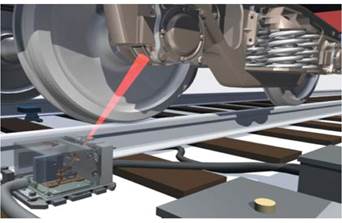

Dragging parts detection systems generate a signal of the presence of a dragging part in the mechanical collision of assemblies and parts of a moving unit extending beyond the lower dimension of the rolling stock with elements of a floor sensor and provides transmission and registration of information about the presence of a ragging part. At the same time, the systems generate an Alarm-2 signal.

Wheel defect detection systems

Wheel defect detection systems provide control of the parameters of the dynamic effect of the wheel on the rail, characterizing the magnitude and type of wheel defect. If the dynamic impact of the wheel on the rail exceeds the set threshold value for a given range of train speeds, information about the location of defective moving units in the train and wheels in the moving unit is transmitted and recorded. In this case, the signals «Alarm-0», «Alarm-1» or«Alarm-2» are generated.

Upper dimension violation detection systems

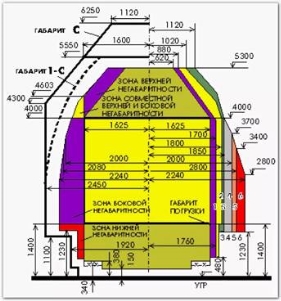

The systems for detecting deviations of the lateral and upper dimensions of rolling stock ensure the generation of a signal when going beyond the established lateral or upper limits of cargo or parts of moving units, the transmission and registration of information about the presence and location of such moving units in the train. At the same time, the systems issue an Alarm-2 signal.

Railcar overload detection systems

Wagon overload detection systems provide the generation of signals when the set value of gross weight, axle load or uneven loading of moving units on the sides or bogies is exceeded, transmission and registration of information about the presence, type of overload and location of overloaded wagons on the train. At the same time, the systems issue an alarm signal «Alarm-1".

Vanishing control devices

The polymer–based rolling stock derailment monitoring device — UKSPS-PM is designed to automatically detect the derailment of rolling stock.

The device is an additional means of improving the safety of train traffic in railway transport.

The device is designed for installation in a railway track with a width of 1520 mm with rails of type P50, P65 in areas with wooden or reinforced concrete sleepers, an additional adjustment kit must be used for installation on a track with rails P75.

The bearing part of the UKSPS-PM is a base made of a dielectric material (pultrusion reinforced fiberglass), on which all elements of the device are mounted.

The device has five sensors connected in series. Three sensors located inside the track are connected to two sensors outside the track by under-rail tires. There are two jumpers at the ends of the device for connection to cable end couplings. The control electrical circuit includes sensors, sub–rail tires and jumpers. The device is triggered when the sensor is destroyed in places with a reduced profile section, depending on the direction of the force action.

The destructible elements of the device are sensors made of steel sheet by stamping with subsequent heat treatment. The sensors are equipped with crumpled elements — impact indicators, for recognition and confirmation of the fact of impact.

Since 2017, UKSPS-PM has been available in two versions:

The device of execution 02 is mounted by means of fastening to an additional wooden sleeper laid in the interstitial space of the rail-sleeper grating.

Advantages of the 02 version device:

— an additional wooden sleeper is used to install the device in the path, laid in an interspan box;

— the wooden sleeper to which the device is attached dampens the vibration loads from the passing train on the sensors of the device, which significantly improves their working conditions and, therefore, eliminates false alarms;

— low labor intensity of installation of the device in the railway track;

— convenient height adjustment of the device relative to the rail head;

— the weight of the mounting kit has been reduced by 2.3 times, which facilitates transportation to the installation site and installation of the device on the way;

— the design of the mounting kit has been changed.

The device of execution 03 is mounted cantilevered to a wooden or reinforced concrete sleeper of a rail-sleeper grating.

The execution devices 02 and 03 are a further upgrade of the UKSPS-PM execution 01.

Devices of both versions comply with the requirements of ETT.00.00.00 «Technical requirements for UKSPS»

Advantages of the 03 version device:

— to install sensors relative to the level of the rail head, rubber adjustment gaskets are used in mounting kits instead of steel gaskets used previously;

— rubber adjusting gaskets reduce vibration loads transmitted to the device from the railway track.

References:

1. Voronova N. I., Razinkin N. E., Dubinsky V. A. Technical operation of passenger cars: textbook.manual. — M.: FGBOU «Educational and methodological center for education in railway transport», 2016. — 211 p.

2. Bykov B. V., Kulikov V. F. The design of the mechanical part of wagons: textbook. the manual. — M.: FGBOU «Educational and methodological center for education in railway transport», 2016. — 247 p.

3. Kobaskaya I. A. Technology of repair of rolling stock: textbook. manual. — M.: FGBOU «Educational and methodological center for education in railway transport», 2016. — 288 p.

4. Nikonov V. A., Meshcherin Yu.V., Kimasov M. A., /Axle boxes with conical bearings of cassette type: recommendations for repair personnel/Wagons and wagon facilities No. 2 2017.